Cable Tray Feeding Motor Control Center

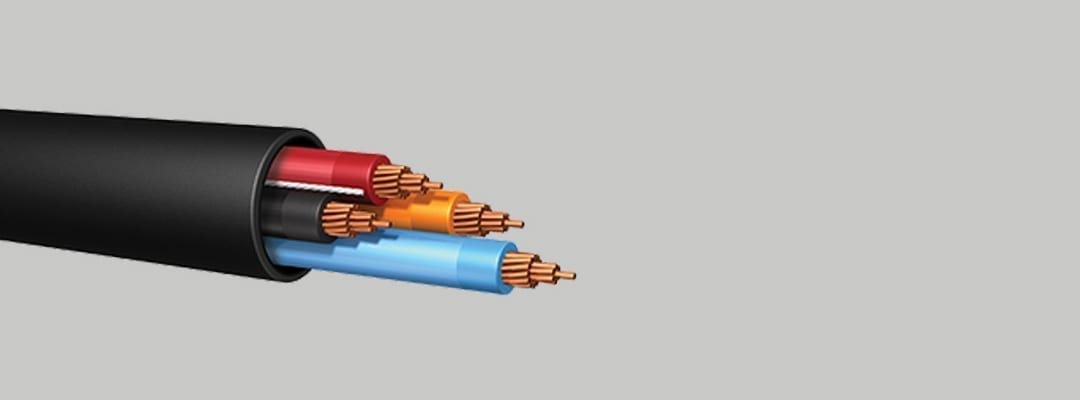

Power and control tray cable comes in a variety of insulation and jacketing combinations for light to heavy-duty industrial applications.

These cables can be used indoors and outdoors, are suitable for direct burial applications and can be used in Class 1 Division 2 and Class 2 Division 2 hazardous locations.

Power and control tray cable is most often used in petrochemical refineries, industrial control systems, intercom systems, traffic controls relay, power extensions and other high-power functions.

With this type of cable, the same tray cable can be used for both power and control. In a substation, for example, tray cable may be used to power fans, coolers and lights. On the control side, it may be used for turning on and off switchgear like relays and breakers, as required.

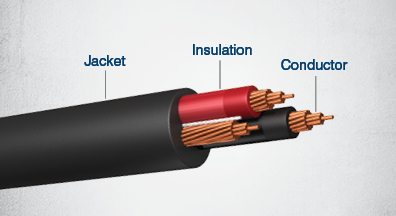

1. Conductor

• Size/gauge (varies)

• Number of conductors or pairs (varies)

2. Color code (varies)

• M1 E1: Colors include black, white, red, green, orange, blue and white.

• M1 E2: No green or white colors. This is common in utility substations.

• Method 4: Uses numbers instead of colors.

3. Shielding

If required: aluminum Mylar foil with a drain wire.

4. Insulation (most common types)

• THHN/THWN (PVC)

• XHHW (XLP)

• EPR

• XLPO

5. Jackets (most common types)

• PVC

• CPE

• Chlorosulfinated polyethylene (CSPE)

• LSZH

6. Grounding

• Green ground

• Bare ground

• Multiple grounds

7. Temperature

• Rated to 75 degrees Celsius for wet locations

• Rated to 90 degrees Celsius for dry locations

8. Locations

• Cable trays

• Ladders

• Troughs

• Channels

• Solid bottom trays

• Similar structures as defined in NEC Articles 318 and 340

• Wire ducts

• Raceways

• Wireways

• Conduit

Outdoor locations require a messenger wire.

9. Applications for control, power and instrumentation

• Manufacturing

• Industrial

• Commercial

• Control circuits for the operation and interconnection of signaling and protection devices

Examples: Chemical and industrial plants, steel mills, utility substations, factories and wind turbines.

Insulation and Shielding

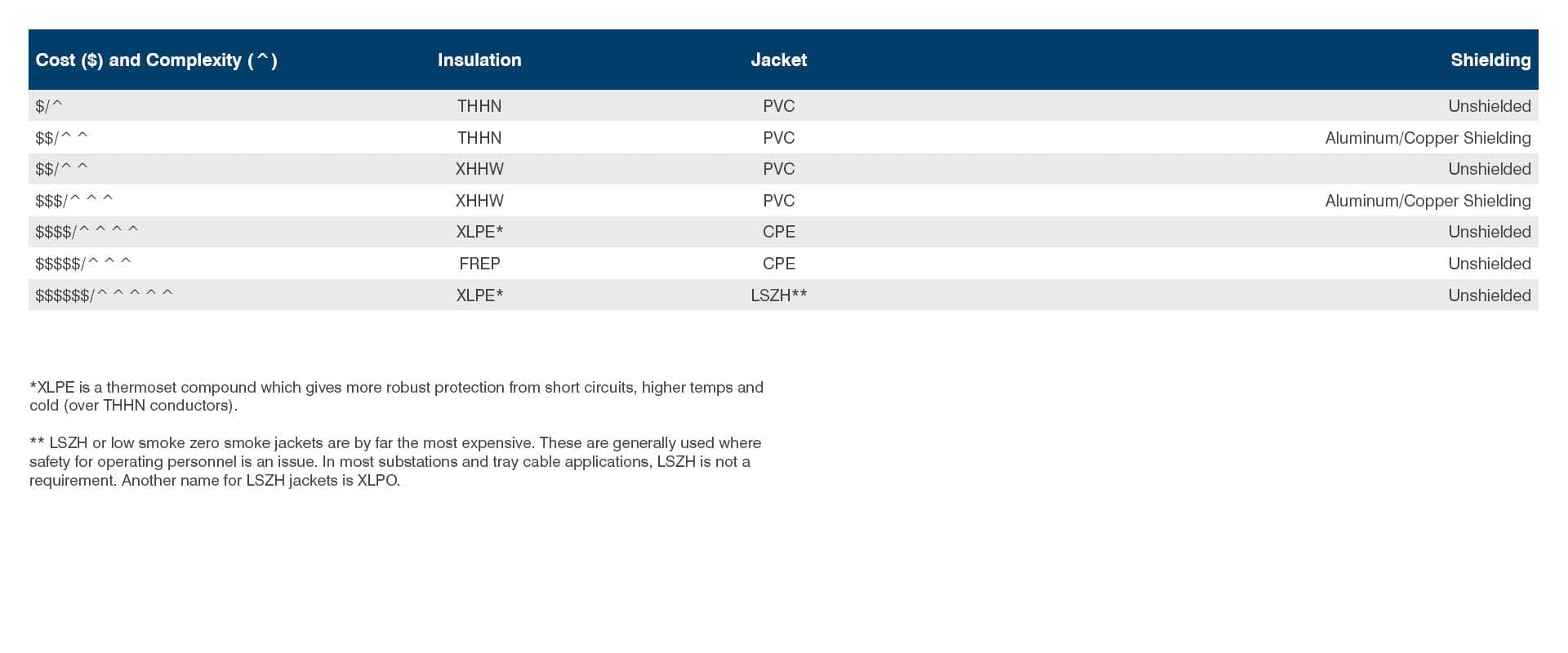

The chart below shows the cost and complexity of different types of insulation, jackets and shielding.

For insulation, the simplest and least expensive power and control tray cables will have THHN-PVC nylon conductors with a PVC jacket.

Aluminum or copper shielding provides a protective shield around the cable. This helps minimize or eliminate the impact of electromotive interference around drives, motors, instrumentation and radio equipment.

Shielding for tray cables generally uses longitudinal or helically wrapped tapes. The tapes are usually polyester-backed aluminum or copper tapes. For heavier industrial and utility applications, use .005-inch annealed copper tapes helically or corrugated and longitudinally applied.

For most power applications, cables can be unshielded to reduce costs. According to Omni Cable, unshielded tray cables are still flame retardant and lead-free, meaning they can be applied safely in a wide variety of uses.

Since tray cables are used in locations such as chemical plants, generating stations and commercial office buildings, their ability to remain safe no matter the surroundings is vital.

Difference Between Class I Division I and Class I Division II Cable

Class 1 Division 1 (2104 NEC 500.5)

This cable is designed for areas where there is or may be an explosive atmosphere of gases or vapors mixed with air present during normal operation, for any reason.

Class 1 Division 2 (2014 NEC 500.5)

This cable is designed for areas where there is an explosive atmosphere of gases or vapors mixed with air when an abnormal condition exists, such as failure of a containment wall or ventilation system.

The site designer and local inspectors determine which class should be used, and the contractor should determine the division. Your distributor does not determine which class and division of products to use.

Standards and Guidelines

UL Requirements

UL 83 – Thermoplastic Wire and Cable

UL 44 – Thermoset Insulated Wire and Cable

UL 1277 – Electrical Power and Control Tray Cable

UL Requirements for Sunlight Resistance and Direct Bury

IEEE 1202 (70K BTU/Hr) Vertical Tray Flame Test – FT4 Canadian Equivalent

CSA 22.3 for -40 Cold Bend – 35 Cold Impact Requirements

Industrial and Utility Standards

NFPA 70 – NEC 336

NEMA WC57/ICEA S-73-532

ICEA T-29-520 210,000 BTU/Hr Flame Test

Border States Stocks and Cuts Tray Cable

Border States is authorized to stock these cables in all locations. We offer a suite of services and solutions, including but not limited to: wire and cable cut-to-length and paralleling, specialized wire and cable reels, wire and cable scrap services, wire and cable pulling heads, and cable management programs. Learn more about our custom wire services here.

Call and let us help meet all of your product and solution needs (866-483-7289).

This article was originally published on April 26, 2017. It was updated and republished on May 18, 2021.

Read more:

What Is Tray Cable? Everything You Need to Know

TC-ER and Direct Bury Cable: What are the Differences?

Source: https://solutions.borderstates.com/power-control-tray-cable-applications/

0 Response to "Cable Tray Feeding Motor Control Center"

Post a Comment